Products

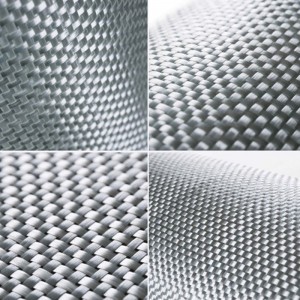

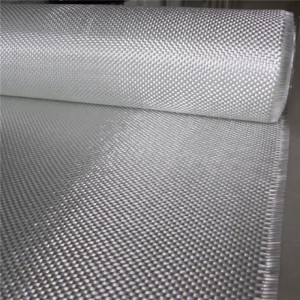

Fiberglass Woven Roving (300, 400, 500, 600, 800g/m2)

Description

Woven roving fiberglass is a heavier fiberglass cloth with an increased fiber content derived from its continuous filaments. This property makes woven roving an extremely strong material that is often used to add thickness to laminates.

However, woven roving has a rougher texture that makes it difficult to effectively adhere another layer of roving or cloth to the surface. Usually woven rovings require a finer fabric to block print. To compensate, roving is generally layered and stitched with chopped strand mat, which saves time in multi-layer layups and allows the roving/chopped strand mixture to be used for the fabrication of large surfaces or objects.

Product Features

1. Even thickness, uniform tension, no fuzz, no stain

2. Fast wet-out in resins, minimal strength loss under damp condition

3. Multi-resin-compatible, like UP/VE/EP

4. Densely aligned fibers, resulting in high dimensional stability and high product strength

4. Easy shape adaptation, Easy impregnation, and good transparency

5. Good drapeability, good moldability and cost-effectiveness

Product Specification

|

Product Code |

Unit Weight ( g/ m2) |

Width ( mm ) |

Length ( m ) |

|

EWR200- 1000 |

200±16 |

1000± 10 |

100±4 |

|

EWR300- 1000 |

300 ± 24 |

1000±10 |

100±4 |

|

EWR400 – 1000 |

400 ± 32 |

1000± 10 |

100±4 |

|

EWR500 – 1000 |

500 ± 40 |

1000± 10 |

100±4 |

|

EWR600 – 1000 |

600± 48 |

1000± 10 |

100±4 |

|

EWR800- 1000 |

800± 64 |

1000± 10 |

100±4 |

|

EWR570- 1000 |

570±46 |

1000± 10 |

100±4 |